Wood Boring tool is one kind of cutting tool. A joiner uses these tools for holes during making or repairing furniture. The common boring tools are braces, bits, gimlet etc. Joiners can also use different chisels for boring work. The hand boring tools get power from the hand pressure whereas electric power dill get power from electricity and battery. Always try to keep sharp of your cutting parts for great result.

Boring drill bit

Boring drill bits are cutting tools that are used to create cylindrical holes. The joiners use these bits with hand brace, hand drill or electric power drills. Following are the different types of bits.

Auger bit

An auger bit contains a helical screw blade for boring holes. They have sizes from 1/4 inch to 1 inch. They are long than others bits. So they can able to bore deep holes which are very smooth. The screw blade can also act as conveyor to remove shavings from the hole. Different types and designs auger bits are available for boring holes.

Expansion bit

Expansion bit is not an indispensable tool. Sometime a joiner has to bore a larger hole as like door hole. They use expansion bit for this purpose. The bit can able to cut over 1 inch holes. It has an adjustable scale, so that you can able to cut the hole as you needed. This bit also has a tang to fit into the hand brace.

Twist bit

The twist bits are inexpensive and extremely available. You can holes from 1/16 to ½ inch. They work best at higher speeds. They have a single or double spiral, two cutting edges and two spurs.

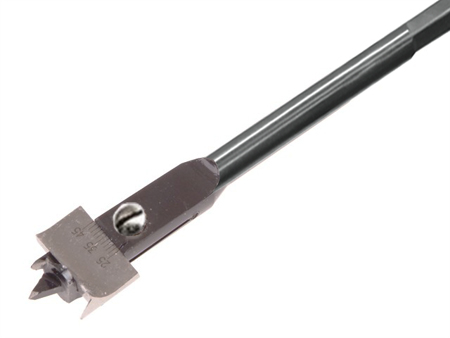

Spade bit

The spade bit has a flat blade which is inexpensive and works very fine. The can hole from 1⁄2″ up to 1 1⁄2” in diameter. Comparatively they can bore quickly but it is not well finest.

Brad point bit

Brad point bits have somewhat similarities to twist bits. It contains a center extended point and a pair of cutting spurs. Joiners like to use these tools for exact drilling like for dowel holes. It bore a very clean hole.

Forstner bit

Forstner bit has a small center point. But this point does not guide the bit. The outer rim guides the bit to cut holes. Therefore carpenters can able to cut curve hole on a workpiece. The drawback of these bits are that if you use handheld drill then the center point may displace at the beginning time of the work from its original point. On the other hand it bore cleanest hole and ideal for overlapping boring. These boring dill bits are costly but it has some powerful qualities which make them indispensible for some woodwork. With these tools a joiner can bore a hole from ¼ ̋ to 2 ̋ sizes. For better result you should use moderate speed.

Center bit

Center bits are used as guider of the next drill bits for producing center holes in a workpiece. They ensure a hole to the right place. It is important for those cases where precision and accuracy are required. For these purposes first use the center bit then follow up with conventional drills. If these bits are used at starting time then the next drill bit does not walking. Moreover it is also used in those cases where joiners want to drill a small sizes hole into a big sizes hole. In addition joiners also use the center bits to make a conical indentation in the end of a workpiece.If you want to know more about “how to center a drill bit” then you can see this video.

Countersink bit

Countersink bit is used to cut a conical hole so that it can allow the head of a bolt or screw. During working time a joiner first bore for the screw than cut the conical hole. This bits are available in six several sizes which are 60°, 82°, 90°, 100°, 110°, or 120°. Among them 82° and 90° Countersinks are most common wood boring tool.

Cobra bit

Cobra bit is used those narrow spaces where do not have operational working environment. Joiners can use this bit as a electric screwdriver. Related video

Hole saw

A hole saw is a steel cylinder with saw teeth for cutting holes. It does not cut so quickly. It is inexpensive and very available in the market. The hole saw is also known as a hole cutter. They are used for large hole up to 6 inches.

bradawl tool

It is very simple tool. Woodworkers use this bradawl tool for boring small and shallow holes. It is vital for boring holes for small to medium sizes screws.

Drills

Drills are the wood boring tools. They are two types which are electric drill and hand drill. The hand drills are useful where the electric drills are not available. Generally they bore the holes sizes from 1mm to 9mm.

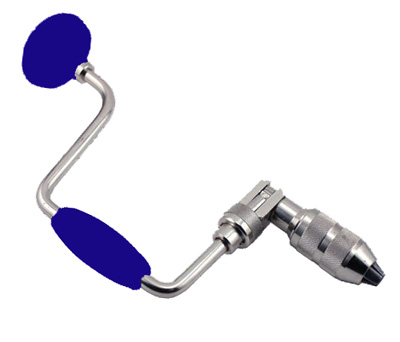

Woodworking brace tool

The Brace, which is a hand tool, is used for boring hole. It consist head, cranked handle, chuck and frame. Some braces may contain ratchet, which is placed just behind chuck. These wood boring tools are ‘U’ shaped. It generates more torque than a hand drill. They are ideal for use with larger bits like auger bits, forstner bits, countersink bits etc.