A combination square is an indispensable tool for woodworkers of all levels of experience. However, with so many different models and brands on the market, it can be difficult to determine which one is right for you. In this article, we will take a comprehensive look at some of the best combination squares available, and help you decide which one is right for your needs. Whether you are a beginner or a seasoned pro, there is sure to be a model that fits your needs!

History of the combination square

The combination square has its origins in ancient Egypt, where it was used for measuring pyramids and other structures. The tool eventually made its way to Greece and Rome, where it was used by carpenters and stonemasons. In the Middle Ages, the combination square was introduced to Europe, where it became an essential tool for builders and craftsmen.

Today, the combination square is used by woodworkers of all levels of experience and is an indispensable tool for any workshop.

Parts of the combination square

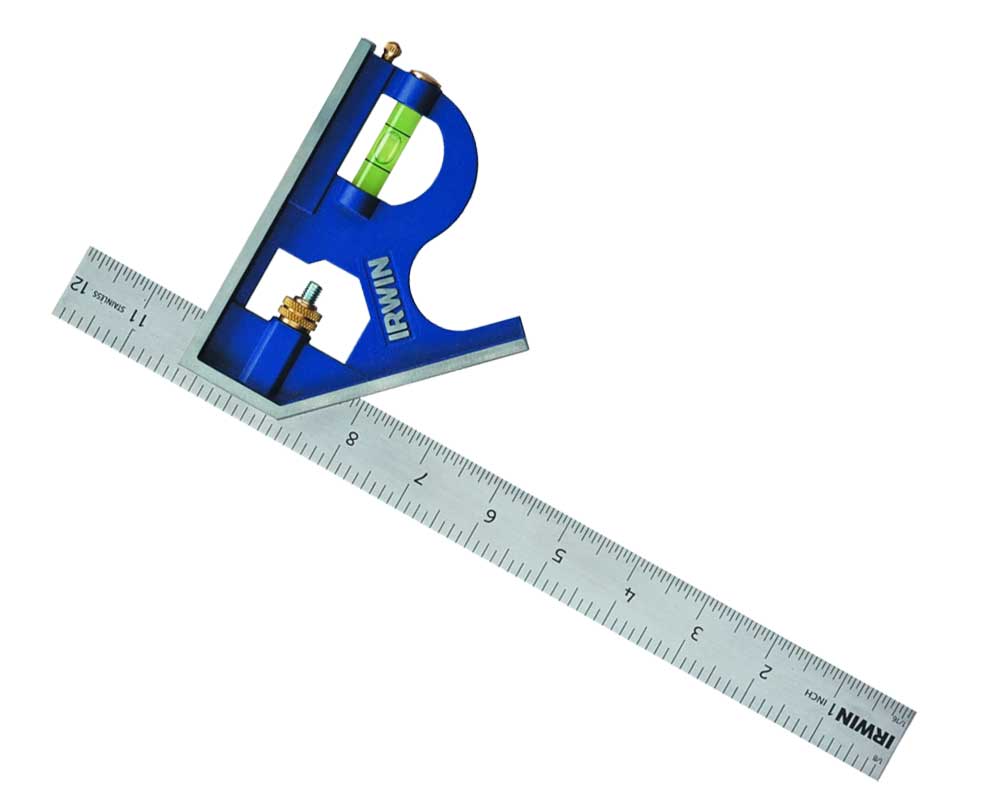

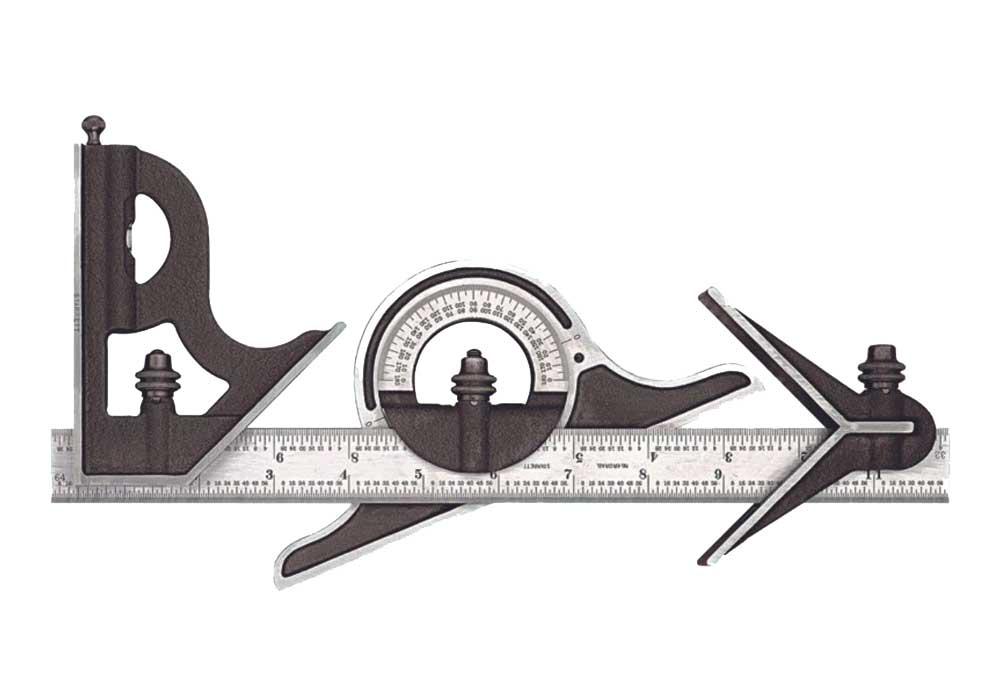

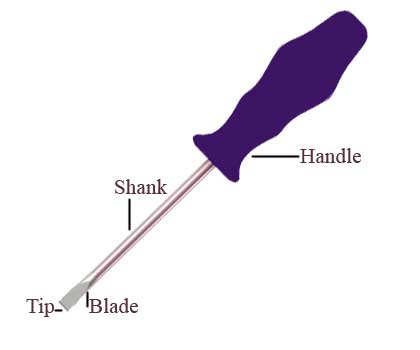

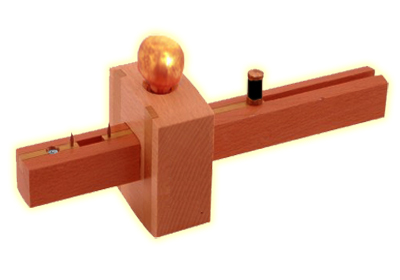

The combination square has three main parts: the head, the blade, and the stock.

The head is the part of the square that contains the rulers or measuring scales. The most common types of heads are those with one straight edge and one ruler, and those with two rulers at 90-degree angles to each other.

The blade is the part of the square that is attached to the head. It is usually made of steel or aluminum, and it is what you use to make your measurements.

The stock is the part of the square that attaches the blade to the head. It is usually made of wood or plastic, and it provides a sturdy base for the blade.

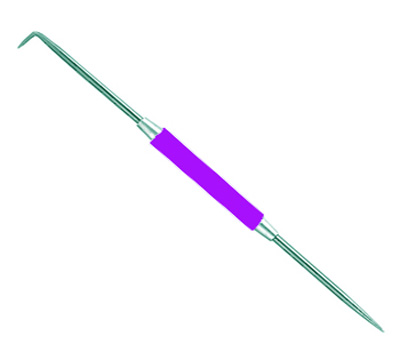

There are also a few other parts that are often found on combination squares, such as a level bubble and a scribe. The level bubble is used to ensure that your square is level, while the scribe can be used to mark lines on your workpiece.

Types of the combination square

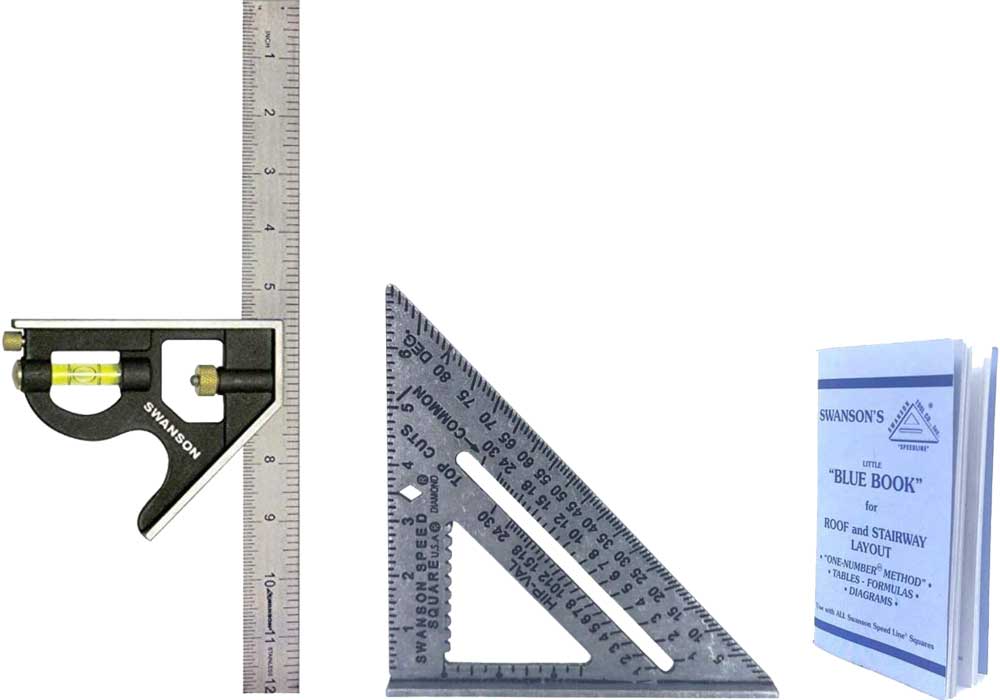

There are several types of combination squares available on the market, each with its own advantages and disadvantages. Here is a quick overview of the most popular types:

-Traditional combination square: This type of square is the most basic and simple to use. It consists of a steel ruler with a 90-degree angle at one end, and a head that can be attached at either end of the ruler. This type of square is great for simple tasks such as measuring and marking 90-degree angles, but it is not very precise.

-Digital combination square: This type of square is more expensive than a traditional one, but it is much more precise. It consists of a digital display that shows the measurements, and a head that can be attached at either end of the ruler. This type of square is great for more precise tasks such as measuring small angles and marking very precise lines.

-Folding combination square: This type of square is similar to a traditional one, but it has a folding head that allows for more versatility. It is great for tasks such as measuring inside and outside corners, and marking lines at any angle.

Now that you know the different types of combination squares available, you can decide which one is right for your needs. If you are just starting out in woodworking, a traditional square will suffice. However, if you need more precision, a digital or folding square would be a better choice. Whichever type you choose, make sure to get one that is made from high-quality materials and is durable. With the right combination square, you will be able to tackle any woodworking project with ease!

Combination square uses

There are a few different ways that you can use a combination square:

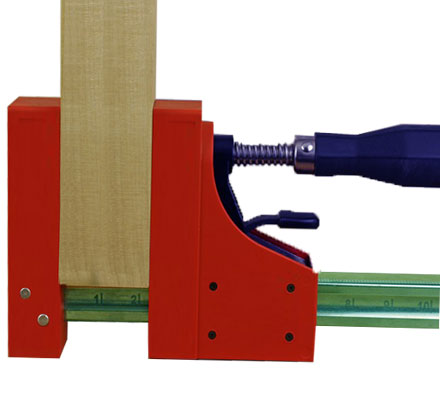

-marking out lines: you can use the head of the combination square to mark out lines on your wood. This is useful for marking out cutting lines, or for drawing lines that you need to follow when shaping your wood.

-measuring angles: the combination square can also be used to measure angles. This is useful for ensuring that your cuts are at the correct angle, or for checking the angle of existing joints.

-checking for square: finally, you can use the combination square to check whether two pieces of wood are perfectly square. This is essential for ensuring that your project will be stable and look good.

Choosing a combination square

With so many different models and brands on the market, it can be difficult to determine which one is right for you. One of the most important things to consider when choosing a combination square is the blade. The blade is the part of the tool that actually makes contact with your workpiece, so it is important to choose one that is made from high-quality materials. Look for a blade that is made from stainless steel or another durable material. Additionally, make sure that the blade is properly hardened and tempered, as this will help ensure a long lifespan.

Another thing to consider is the handle. The handle is what you will grip when using the tool, so it is important to choose one that is comfortable for you. Some handles are made from wood, while others are made from plastic or metal. Consider how the tool will feel in your hand, and choose a model with a handle that is comfortable for you.

Finally, consider the price. Combination squares are available at a wide range of prices, so it is important to find one that fits your budget. However, remember that the quality of the tool is more important than the price. If you are only going to use the tool occasionally, you may not need to spend as much as someone who is going to use it on a daily basis. However, if you plan on using the tool frequently, it is worth investing in a higher-quality model.

Conclusion

No matter what your needs are, there is sure to be a combination square that is right for you. With so many different models available, it is easy to find one that fits your budget and your needs. By considering the factors discussed above, you can be sure to find the perfect model for your woodworking shop! Have you ever used a combination square? What are your thoughts on them? Let us know in the comments below!