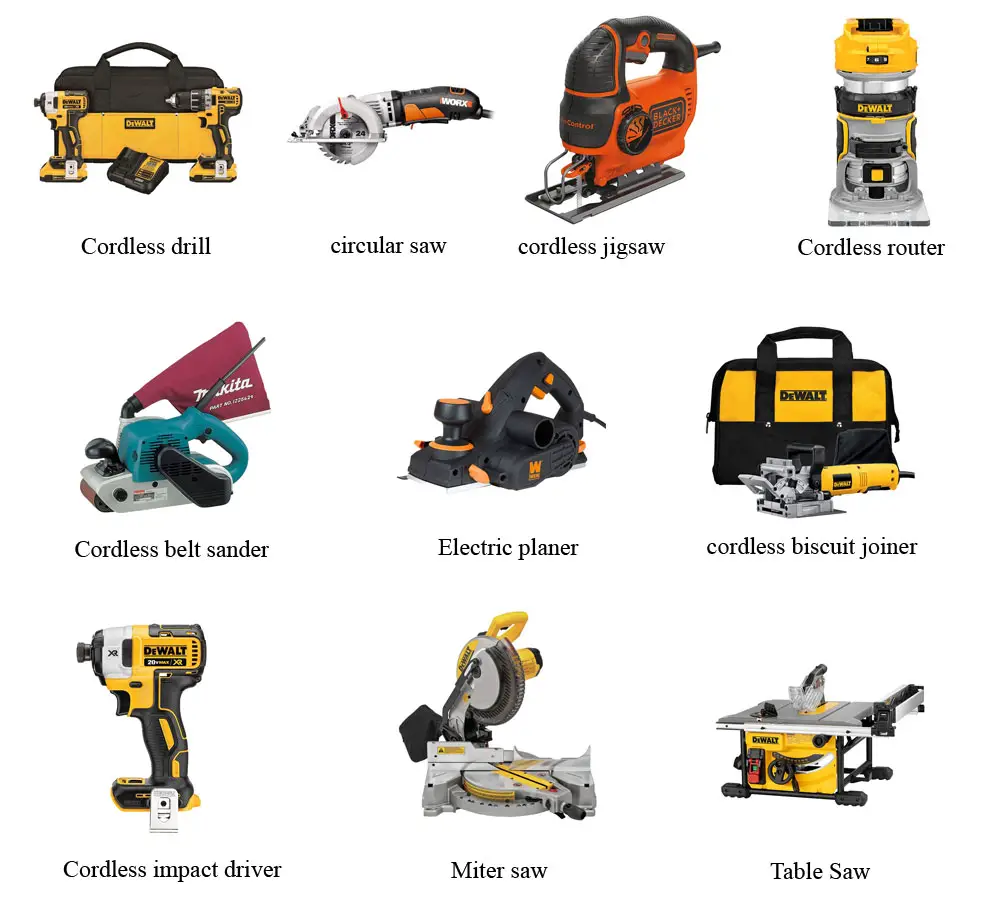

If you’re interested in woodworking, then it’s important to have the right tools. Power tools make the process a lot easier and can help you create beautiful pieces of furniture or other items. In this article, we will discuss 10 basic power tools that every woodworker should own. When it comes to woodworking, having the right tools can make all the difference. Be sure to do your research before making any purchases, and invest in quality tools that will last for years to come.

01. Cordless drill

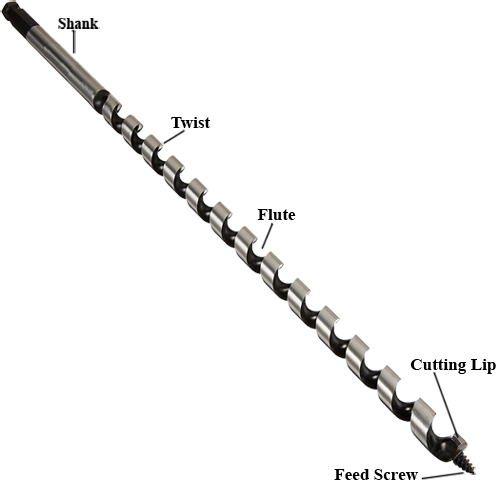

Cordless drill drivers are one of the most versatile and essential power tools for woodworking. They are perfect for drilling holes and driving screws into wood. Cordless drill drivers come in a variety of sizes, so it’s important to choose one that will be comfortable for you to use.

When choosing a cordless drill driver, it’s important to consider the battery life and the speed at which the drill spins. A good quality drill will have multiple speed settings and a reversible direction so that you can use it for drilling into various materials. You’ll also want to decide whether you want a cordless drill with a keyless chuck or one that has a keyed chuck. Keyless chucks are easier to use, but they may not be as durable as keyed chucks.

Once you’ve chosen the perfect cordless drill driver, be sure to read the instructions carefully before using it. This will help you avoid any accidents and ensure that you use the drill correctly.

02. Electric circular saw

An electric circular saw is a handheld power tool that is used for cutting wood. It has a circular blade that spins at high speeds and can cut through wood very easily. This makes it an essential tool for any woodworker. You can use it to make straight cuts, rip cuts, or even curved cuts.

The most important thing to remember when using an electric circular saw is to always use safety gear. This includes eye protection, gloves, and a dust mask. Always make sure the area around you is clear of debris before starting the saw. And never try to cut through metal with an electric circular saw, as this can damage the blade.

With these tips in mind, an electric circular saw is a great tool to have in your woodworking arsenal. It can make quick work of any cutting job and help you create beautiful pieces of furniture or other items. So if you’re just getting started in woodworking, be sure to pick up an electric circular saw. It will make your life a lot easier!

03. Cordless jigsaw

A cordless jigsaw is a great basic power tool for woodworkers of all levels. It can be used to make straight or curved cuts, and it’s relatively easy to control. They can also be used to create decorative patterns or designs on your project pieces. When choosing a cordless jigsaw, be sure to pick one that is comfortable to hold and has good battery life.

04. Cordless router

A cordless router is one of the most versatile and essential power tools that a woodworker can own. It can be used for a variety of tasks, such as shaping edges, making joints, and hollowing out areas. A cordless router is also very portable, which makes it ideal for working in tight spaces or on delicate projects.

There are a few things to keep in mind when using a cordless router. First, always use sharp bits and blades. Second, take care not to overheat the router by working too long in one spot. Finally, be sure to wear eye and ear protection when using this tool.

05. Cordless belt sander

Cordless belt sanders are one of the basic power tools for woodworking. They make the process of sanding a lot easier and can help you create beautiful pieces of furniture or other items. They are great for quickly removing excess material from a project piece. They can also be used to create a smooth, finished surface on a piece of wood. Cordless belt sanders come in different sizes, so it is important to choose one that will fit your needs. There are also different types of cordless belt sanders, so it is important to choose one that will work best for your project. They can save you time and money in the long run.

06. Handheld electric planer

A handheld electric planer is a power tool that is used to smooth out rough surfaces on wood. It can also be used to shave off small pieces of wood, making it a versatile tool for woodworking. A handheld electric planer is an essential tool for any woodworker, as it can save you a lot of time and effort when working on a project.

There are many different types of handheld electric planers on the market, so it is important to choose one that is right for you. Some factors to consider include the size of the unit, the power level, and the features that are available. You should also make sure that the planer you choose is compatible with the type of wood you will be working with.

Once you have chosen the perfect handheld electric planer for your needs, it is time to start using it! Always read the manufacturer’s instructions before operating the tool, and make sure to wear appropriate safety gear when working.

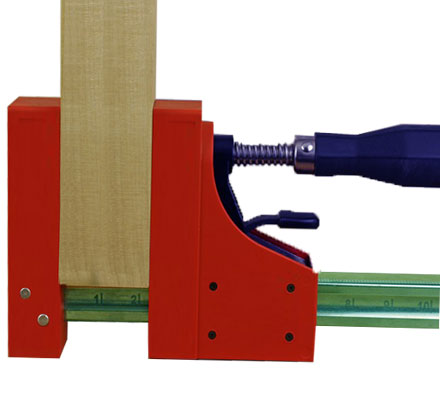

07. Cordless biscuit joiner

A biscuit joiner, also known as a plate joiner, is a woodworking tool used to join two pieces of wood together. It is essentially a handheld router that cuts a semi-circular groove in one piece of wood and into which a small “biscuit” made of compressed wood fibers is inserted. The biscuit joiner is then used to clamp the two pieces of wood together while the glue dries, resulting in a strong joint.

There are many different brands and models of biscuit joiners on the market, but they all perform the same basic function. Many woodworkers prefer cordless biscuit joiners because they offer greater flexibility and mobility, especially when working on large projects. When choosing a biscuit joiner, it is important to consider the size of the biscuits that it uses.

08. Cordless impact driver

Cordless impact drivers are one of the most basic and essential power tools for woodworking. They are very versatile and can be used for a variety of tasks, such as driving screws and nails, drilling holes, and even loosening bolts. Cordless impact drivers are very powerful and can make your work go much faster. They are also relatively inexpensive, so they are a great investment for any woodworker. So, if you’re looking for a basic power tool that every woodworker should own, then a cordless impact driver is a great choice.

09. Electric miter saw

An electric miter saw is one of the most important tools for any woodworker. It allows you to make precise cuts at a variety of angles, which is essential for many woodworking projects. Miter saws come in a variety of sizes and styles, so it’s important to choose one that will best suit your needs.

There are two main types of electric miter saws: sliding and compound. Sliding miter saws have a blade that slides along a rail, which allows you to make long, precise cuts. Compound miter saws have a blade that pivots on an axis, which allows you to make more intricate cuts.

No matter what type of electric miter saw you choose, it’s important to read the instructions carefully and practice safely before attempting any projects. With the right tools and a little practice, you’ll be able to create beautiful woodworking projects that will last for years to come.

10. Electric table saw

An electric table saw is one of the most important power tools for a woodworker. It can make quick, precise cuts in wood, and is essential for many woodworking projects. Table saws come in a variety of sizes and styles, so it’s important to choose one that will suit your needs. When shopping for an electric table saw, keep in mind the size of the projects you’ll be working on and the amount of space you have in your workshop.

One important factor to consider when purchasing power tools is the warranty. Many tools come with a limited warranty, so be sure to read the fine print before making your purchase. It’s also important to register your power tool so that you can take advantage of any warranty coverage that might be available.

Another factor to consider when purchasing power tools is the accessories that are available for them. Many manufacturers offer a variety of accessories that can make using their tools even more versatile and convenient. Be sure to check out what’s available before making your final decision on which tool to purchase.

Conclusion | 10 Basic Power Tools for Woodworking

If you’re just getting started in woodworking, then it’s important to have the right tools. In this article, we discussed ten basic power tools that every woodworker should own. These tools will make your life much easier and help you create beautiful pieces of furniture or other items. Do you have any other essential power tools that you use for your projects? Let us know in the comments below! Thanks for reading and happy woodworking!