Are you a woodworking enthusiast or just starting your journey in carpentry? A carpenter toolbox is an essential tool that every carpenter must-have. It’s like a treasure box that contains all the essential tools needed to make beautiful crafts and furniture. In this post, we’ll explore what a carpenter toolbox is, its components, types of boxes available in the market, and how to choose the right one for you. So let’s dive into this interesting topic!

A carpenter’s tool box is a container that holds various tools and equipment that are used by carpenters to perform their work. It can come in different shapes and sizes and can be made of various materials, including metal, plastic, or wood.

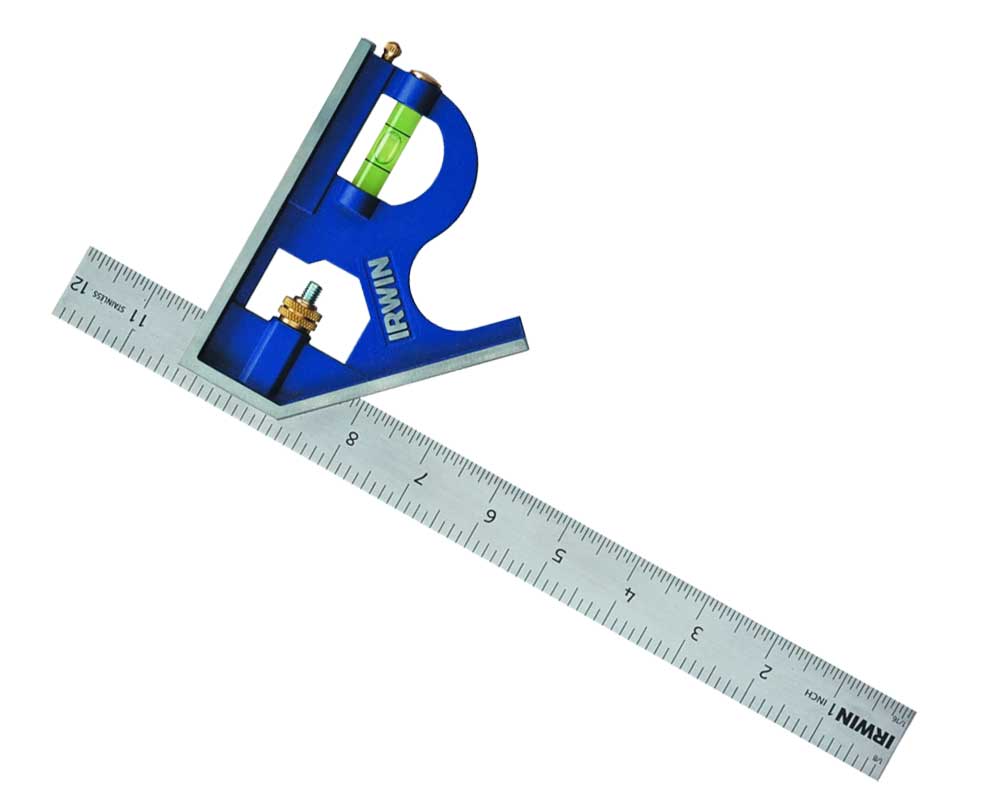

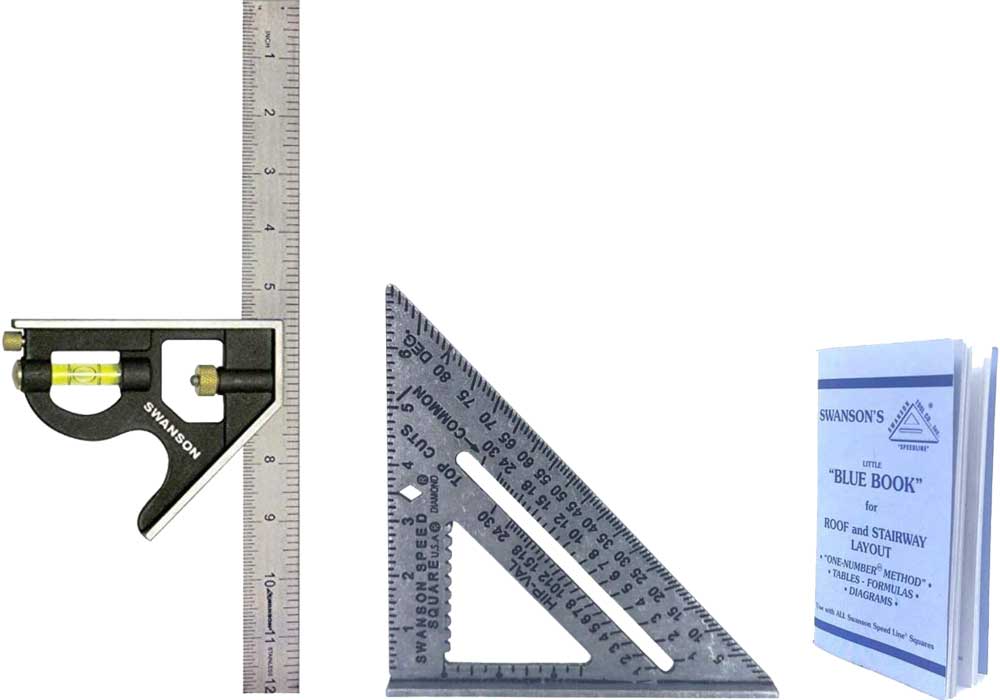

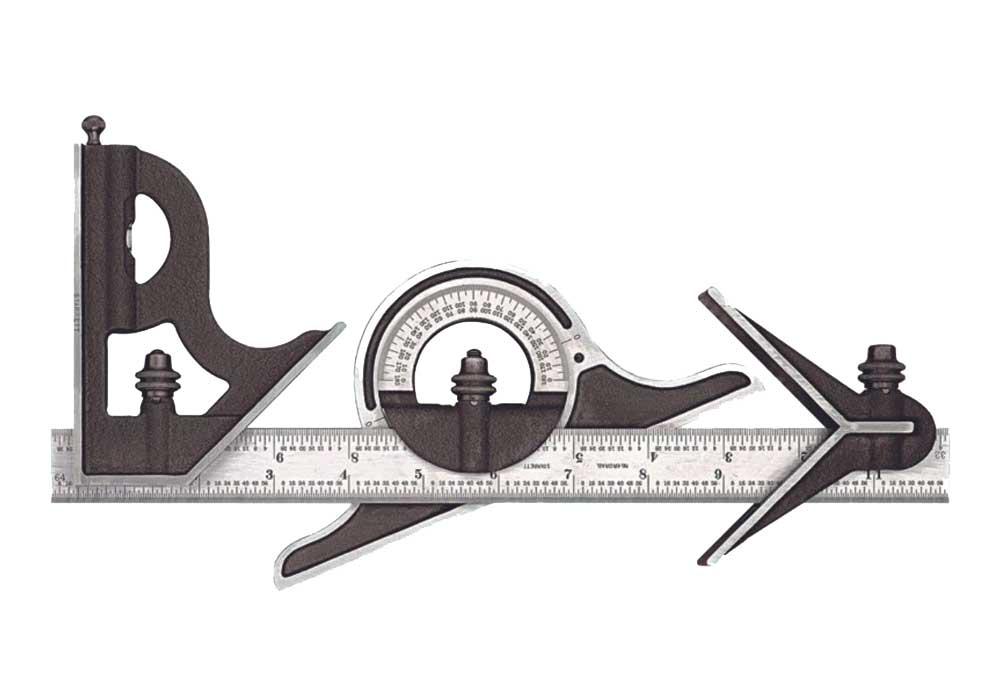

The tools inside a carpenter’s tool box can vary depending on the type of carpentry work being done, but typically include items such as hammers, saws, chisels, screwdrivers, pliers, measuring tapes, levels, squares, clamps, drills, and more.

The different types of carpenter tool boxes

There are many different types of carpenter tool boxes available on the market, each designed for a specific purpose. Here are some of the most common types:

- The Standard Tool Box: This is the most basic type of carpenter tool box, and usually consists of one or two compartments for storing tools.

- The Portable Tool Box: These are small to medium-sized boxes that are easy to carry around and transport. They are usually made of durable plastic or metal. It typically has wheels and a handle for easy transportation.

- The Stackable Tool Box: This type of carpenter tool box is designed to be stacked on top of another tool box, creating a taller storage option.

- The Rolling Tool Box: This type of carpenter tool box has wheels and is designed to be rolled around a job site. It is often used in conjunction with a portable tool box.

- Chest tool boxes: These are large, heavy-duty boxes that are designed to hold a large number of tools. They usually have multiple compartments and drawers for organizing tools and are made of durable materials like metal.

- Workbench tool boxes: These tool boxes are designed to be integrated into a workbench, providing a storage area for tools underneath the work surface.

- Tool bags: These are soft-sided tool storage solutions that are made of durable fabric and have multiple pockets for organizing tools. They are lightweight and easy to carry around.

- Tool belts: These are wearable tool storage solutions that consist of a belt and various pouches and pockets for holding tools. They are designed to keep tools close at hand while leaving the user’s hands free.

The type of tool box a carpenter chooses will depend on their specific needs and preferences. A portable tool box or tool bag may be ideal for carpenters who need to carry their tools to different job sites, while a chest tool box or workbench tool box may be better suited for those who work in a fixed location.

What to look for when purchasing a carpenter tool box

When purchasing a carpenter tool box, there are several factors to consider to ensure that you choose the right one for your needs. Here are some things to look for:

- Size: Consider the size of the tool box and whether it will be able to accommodate all of your tools. You’ll want to choose a tool box that is large enough to hold everything you need but not so large that it becomes cumbersome to transport.

- Durability: Look for a tool box that is made of high-quality materials and is built to last. Metal tool boxes are usually more durable than plastic ones, but they can be heavier and more expensive.

- Portability: Consider whether you will need to transport your tool box frequently. If so, look for a tool box with wheels or a handle for easy transport.

- Organization: Look for a tool box that has compartments or drawers for organizing your tools. This will make it easier to find what you need when you need it.

- Security: Consider whether you need a tool box with a lock or other security features to prevent theft or unauthorized access.

- Price: Tool boxes can range in price from relatively inexpensive to very expensive. Consider your budget and choose a tool box that fits within it while still meeting your needs.

- Brand and Warranty: Choose a reputable brand with a good warranty to ensure that your tool box will be reliable and long-lasting.

Overall, choosing the right carpenter tool box is about finding the right balance between size, durability, portability, organization, security, and price to meet your specific needs.

The best carpenter tool boxes on the market

There are many different types of carpenter tool boxes on the market. Some are better than others. Here is a list of the best carpenter tool boxes on the market:

1. DeWalt ToughSystem DS450 22 in. Mobile Tool Box:

This is a heavy-duty tool box that is made of durable materials and has a capacity of 110 pounds. It features a telescoping handle and heavy-duty wheels for easy transport, and it can be stacked with other DeWalt ToughSystem modules. It also has a lot of compartments to store all of your tools.

2. Stanley 028001L 28-Inch Structural Foam Toolbox:

This is a lightweight yet durable tool box that is made of structural foam and has a capacity of 28 quarts. It features a removable tray and a built-in padlock eye for security.

3. Klein Tools 55452RTB Rolling Tool Bag:

his is a versatile tool bag that can hold up to 100 pounds of tools. It features a telescoping handle and wheels for easy transport and has a variety of pockets and compartments for organization.

4. Keter Master Pro Masterloader 17191709 Tool Trolley

The Keter New Masterloader Plastic Utility Tool Box is one of the best carpenter tool boxes on the market. It is made out of durable plastic and has a lot of compartments and trays to organize your tools.

5. Husky 230381 22 in. Connect Rolling System Tool Box

Husky 22 in. Connect Rolling System Tool Box: This is a modular rolling tool box that can be customized to meet your specific needs. It features a telescoping handle and wheels for easy transport and can be stacked with other Husky Connect System units.

Ultimately, the best carpenter tool box for you will depend on your specific needs and preferences. Consider factors such as size, durability, portability, organization, security, and price when choosing a tool box that meets your needs.

How to care for your carpenter tool box

Assuming you are referring to a tool box used by carpenters, here are some tips on how to care for it:

- Keep the tool box clean and free of sawdust or other debris. This will help extend its life and prevent rusting.

- Oil the hinges and locks: Use a lightweight oil such as WD-40 to lubricate the hinges and locks on your tool box. This will help keep them working smoothly and prevent rust.

- Store the tool box in a cool, dry place when not in use. Heat and moisture can damage the tools and cause them to rust.

- Don’t overload your tool box: Be careful not to overload your tool box with too many heavy tools or accessories. This can cause the tool box to become damaged or difficult to transport.

- Use the right tool for the job: Avoid using your tool box as a workbench or stepping stool, as this can cause damage to the box and put unnecessary strain on the hinges and locks.

- Check the tool box regularly for damage: Inspect your tool box regularly for signs of wear and tear or damage. If you notice any cracks, dents, or other damage, address it promptly to prevent further damage.

By following these tips, you can help ensure that your carpenter tool box lasts for years and keeps your tools in good condition.

Conclusion

A carpenter’s tool box is an essential item for any professional or amateur woodworker. It helps to keep tools organized and ready for use, as well as providing a portable solution that allows you to bring the correct tools wherever you go. With a wide range of sizes and styles available, there is sure to be a carpenter’s toolbox that meets your needs – no matter how large or small your projects may be!